Maintaining the shock absorbers on a classic car can help ensure that the vehicle continues to provide a smooth and comfortable ride, as well as improve handling and stability.

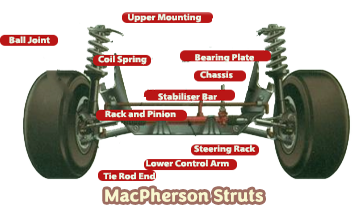

The gas strut is a type of shock absorber commonly found in cars produced during the Fifties and Sixties in the UK and Europe. Sometimes known as a gas spring, the gas strut shock absorber that employs compressed gas to provide resistance to suspension movement. Gas stuts consist of a cylinder and a piston, both are which are firmly sealed to keep the compressed gas inside. The struts operate through a piston, connected to the suspension arm and a cylinder which is attached to the vehicle frame. Classic car suspension is designed to spring into action when the wheel of a car hits a bump or hole in the road. At that point the wheel on that side of the will rise and the suspension will contract.

Classic car suspension is designed to spring into action when the wheel of a car hits a bump or hole in the road. At that point the wheel on that side of the will rise and the suspension will contract.

The contraction will cause the gas inside the cylinder to compress, creating resistance to the suspension's movement.

As the suspension arm rises, the gas inside the cylinder compresses, producing an opposing force to that of the suspension arm or strut, reducing considerably the levels of vibration and impact in the vehicle.

Gas struts fall into two categories- monotube and twin-tube.

Twin-tube gas struts have two cylinders, whereas monotube gas struts have one.

Advantageous for a variety of reasons, including their durability and high performance, gas strut shock absorbers are also relatively simple to maintain and, inexpensive to replace. In addition, gas struts are more resistant to leaks than mechanical shock absorbers.

There are several reasons why gas struts can fail, with the most common being either cylinder or piston leaks.

Over time, simple wear and tear will play their part as well as overexposure to extreme temperatures.

Over time, simple wear and tear will play their part as well as overexposure to extreme temperatures.

Internal components that are worn or damaged are another common cause of failure. The moving parts inside the gas strut can become worn or damaged over time, reducing its ability to absorb vibrations and impacts.

![]() Examine the shock absorbers by pushing down on the corners of the vehicle. If the shocks are working properly, the vehicle should rebound quickly and not sway or continue to bounce.

Examine the shock absorbers by pushing down on the corners of the vehicle. If the shocks are working properly, the vehicle should rebound quickly and not sway or continue to bounce.

![]() Rust can cause damage to the shocks over time, so it's important to regularly inspect the shocks for signs of rust. If rust is present, have it removed and treated to prevent further corrosion.

Rust can cause damage to the shocks over time, so it's important to regularly inspect the shocks for signs of rust. If rust is present, have it removed and treated to prevent further corrosion.

![]() Inspect the spring on the shock absorbers. Ensure that they are not damaged or loose. If they are worn out or damaged, they can cause harm to the shock absorbers and will need to be replaced.

Inspect the spring on the shock absorbers. Ensure that they are not damaged or loose. If they are worn out or damaged, they can cause harm to the shock absorbers and will need to be replaced.

It's important to keep in mind that classic cars may have different types of shock absorbers than the modern cars, it's always better to consult an owner’s manual for the specific make and model of your classic car if there is one available.

It's important to keep in mind that classic cars may have different types of shock absorbers than the modern cars, it's always better to consult an owner’s manual for the specific make and model of your classic car if there is one available.

Regular inspection and maintenance can help extend the life of a classic car's shock absorbers and can avoid costly repairs in the future.

Back to the homepage- and don't spare the horsepower.

ub4