It’s a well-known phenomenon that when a classic car has undergone a major restoration, the principal focuses of attention are those that immediately apparent- the mechanics, the bodywork, the paintwork, the exterior and the interior.

Very little people will pay attention to what is gong on in the underside oof the vehicle- yet they play the most significant part in ensuring that the drivers have a comfortable ride and reach their destination safely.

The principal components of underbody system are the brakes, axles, steering, suspension as well as another number of important components, working together as part of a seamless design involving a lot of complexity.

The principal components of underbody system are the brakes, axles, steering, suspension as well as another number of important components, working together as part of a seamless design involving a lot of complexity.

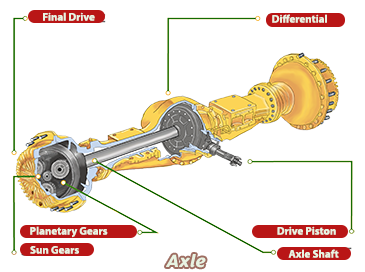

There are parts working together in perfect synchrony to keep the running smoothly. One part, in particular, is important for connecting your engine to the wheels it powers: the axle.

The axles in the car are crucial components that must be maintained properly, despite their sturdy construction.It is important to take good care of the axles to ensure safe operation of the vehicle. In case you perceive unusual sounds or detect any indications such as clunking when shifting gears, vibrations, or if the car is running smoothly but not moving, it is likely that the axles demand maintenance. It is advisable to take the vehicle to a certified mechanic for a thorough inspection.

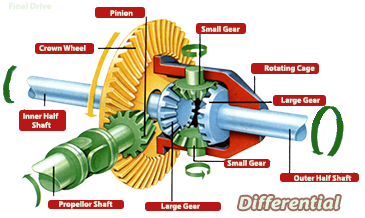

To ensure that a classic car runs smoothly, it is crucial to properly maintain the differential. The differential is a crucial component that facilitates the transfer of power from the engine to the wheels. Neglecting its maintenance can result in severe issues.

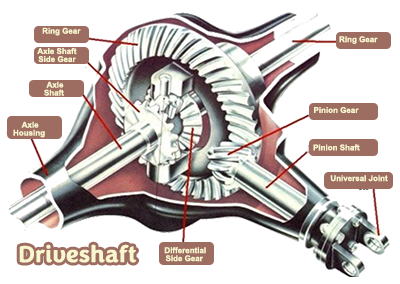

The drive shaft is an essential component of a vehicle's powertrain system that facilitates the transfer of engine torque from the gearbox or differential to the wheels, enabling the vehicle to move forward or backward. To achieve perfect synchronisation between joints, the system must account for any variations in angle or length that may result from manoeuvring and deflection.The drive shafts in front-wheel drive vehicles are typically composed of three main components: the outboard fixed joint, the inboard constant velocity joint, and the connecting shaft. The anti-lock system ring and torsion damper are among the components included in the system. The constant velocity joint, which is also known as the outboard fixed ball joint, has a fundamental design that originated in the pre-war era.

The driveshaft is recognised as being among the most crucial components, responsible for transmitting rotational power from the engine to the rear differential. Essentially a rotating tube that connects these two components the driveshaft ( or prop shaft as it is sometimes known) enables the transfer of torque to the wheels. Power from the front to the back of the device causes it to spin and by doing so allows the gearbox to transfer torque to the differential, which transmits torque to the wheels, enabling the vehicle to move.

The driveshaft is recognised as being among the most crucial components, responsible for transmitting rotational power from the engine to the rear differential. Essentially a rotating tube that connects these two components the driveshaft ( or prop shaft as it is sometimes known) enables the transfer of torque to the wheels. Power from the front to the back of the device causes it to spin and by doing so allows the gearbox to transfer torque to the differential, which transmits torque to the wheels, enabling the vehicle to move.

The drive shaft is an essential component in the powertrain system of a vehicle, with its primary role to transmit the rotational force generated by the engine to the wheels via the gearbox or differential. This action allows the wheels to turn and propel the vehicle forward. To achieve perfect synchronisation between joints, the compensation mechanism must account for any variations in angle or length caused by manoeuvring and deflection.

In front-wheel drive vehicles the drive shafts typically comprise three main components: the outboard fixed joint, the inboard constant velocity joint, and the connecting shaft. The components mentioned are integral parts of a vehicle's braking system.

Issues with drive shaft are commonly indicated by knocking sounds while driving around tight corners, accelerating, or when the suspension is being compressed and extended. It is advisable to schedule an appointment with a specialised garage if you notice any of these symptoms to prevent compromising the safety of your vehicle.

Issues with drive shaft are commonly indicated by knocking sounds while driving around tight corners, accelerating, or when the suspension is being compressed and extended. It is advisable to schedule an appointment with a specialised garage if you notice any of these symptoms to prevent compromising the safety of your vehicle.

To ensure that a classic car runs smoothly, it is crucial to properly maintain its differential. The differential is a crucial component that facilitates the transfer of power from the engine to the wheels.

The differential is a crucial mechanical device found in every type of automobile. The primary purpose of a differential is to compensate for the difference in distance travelled by the inner and outer wheels of a vehicle when turning a corner. When the drive wheels rotate together, they can experience a jumping motion due to the variance in distance travelled by the outer tyre versus the inner tyre. Proper maintenance of a classic car's differential is crucial for optimal performance and longevity of the vehicle. The differential is a crucial component of a vehicle's drivetrain system. Its primary function is to transfer power from the engine to the wheels. Regular maintenance of the differential is crucial to prevent major issues from arising. The differential is a crucial mechanical component in a vehicle's drivetrain system that allows the wheels to rotate at different speeds while ensuring that power and torque are distributed evenly to each wheel.

The differential is a crucial mechanical component in a vehicle's drivetrain system that allows the wheels to rotate at different speeds while ensuring that power and torque are distributed evenly to each wheel.

The front differential is a crucial component of a vehicle's drivetrain system that facilitates the transfer of power from the gearbox to the front wheels. The differential is an integral part of a vehicle's drivetrain system that allows the wheels to rotate at different speeds. This is a critical function that is necessary for executing turns and maintaining optimal road grip.

In most front-wheel-drive (FWD) vehicles, the differential is typically situated adjacent to the gearbox within a shared housing. The integrated unit that combines the gearbox, differential, and axle shafts is commonly referred to as a transaxle.

In vehicles that utilise rear-wheel-drive (RWD), the differential is typically positioned between the two rear wheels and is linked to the gearbox via a driveshaft.

Vehicles that are equipped with all-wheel-drive (AWD) or four-wheel-drive (4WD) have a centre differential or transfer case that enables the distribution of power between the front and rear wheels.  Another important component to an underbody refurbishment is the steering, preferably under a few different conditions. If the steering wheel starts to shudder or wander at certain speeds, means that the front end may need a rebuild.

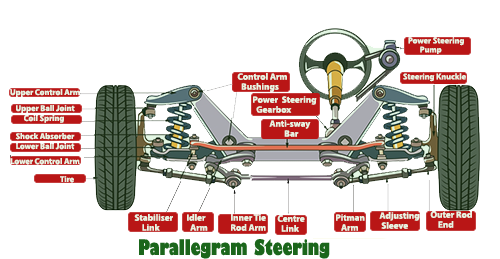

Another important component to an underbody refurbishment is the steering, preferably under a few different conditions. If the steering wheel starts to shudder or wander at certain speeds, means that the front end may need a rebuild.

If there is a lot of play in the steering wheel before the car starts to tum, the steering linkage may be worn, or the steering box may need an overhaul.

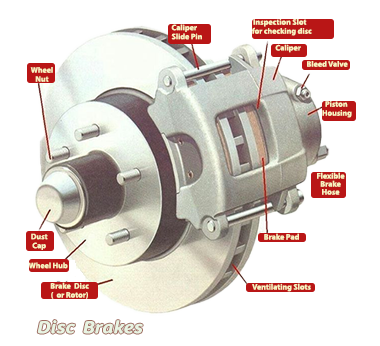

Most UK and European classic cars of the Fifties and the early Sixties came fitted with drum brakes in the front, which were by then regarded as being cumbersome and outdated.

Most UK and European classic cars of the Fifties and the early Sixties came fitted with drum brakes in the front, which were by then regarded as being cumbersome and outdated.

Unless the restorer is a stickler for authenticity, they will follow the trend to replace the drums with discs, which are so much better in many ways and will not cost a fortune to replace.

If the restorer has a large budget and intends to fit a more powerful engine then they should consider installing power-assisted brakes. However, it will be an unnecessary expense if the car's power is not to be increased.

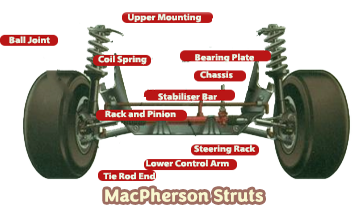

No less important in a classic car is its suspension.

No less important in a classic car is its suspension.

The main purpose of a car's suspension is simply to keep all four wheels on the road. Even if the vehicle will be riding on the finest of tyres after the restoration, they will provide precious little in the way of road-holding if the suspension is not spot on.

Costs of these parts are usually low, while quality is fairly high.

The same procedures apply to the vehicle's shock absorbers. Going back to the pre-war years, hydraulic type shock absorbers were popular and remained so until the Sixties. It was then that they were replaced by telescopic shock absorbers which are popular today.

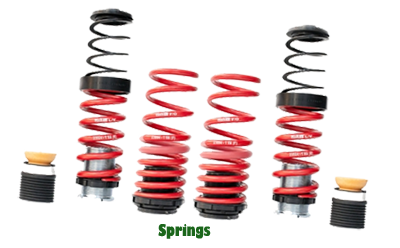

When a wheel goes over a bump in the road, the suspension spring allows for an according adjustment allowing the vehicle floor to remain level.

The suspension spring provides essential movement for the wheels while the shock absorber act as a form of vibration damper for the spring.

Hardly any system connects the driver so directly to his or her car than its steering. A variety of mechanical solutions exist to make the car change direction as the driver wishes.

Nearly all common types of steering follow the so-called 'Ackermann' principle, developed by the renowned German of hat same name more than two hundred years ago. The revolutionary principle behind the Ackermann theory is that the axle itself does not turn, the front wheels instead.

Nearly all common types of steering follow the so-called 'Ackermann' principle, developed by the renowned German of hat same name more than two hundred years ago. The revolutionary principle behind the Ackermann theory is that the axle itself does not turn, the front wheels instead.

Most European and UK cars of the Fifties and Sixties were fitted with rack and pinion steering.

Since then, this design has consistently proved to be not only effective, but compact and inexpensive to produce and maintain.

In smaller family saloons and sports tourers, there is no real reason to change anything, only to ensure that the system is in the best of working condition.

In smaller family saloons and sports tourers, there is no real reason to change anything, only to ensure that the system is in the best of working condition.

Most of the larger saloons produced during the Fifties and Sixties were famous for their cumbersome steering. Restorers who want to improve their driving experience often consider fitting power steering, which will dramatically improve their driving experience. Especially if the car is to be driven in the city.

Back to the homepage- and don't spare the horsepower.

ub4