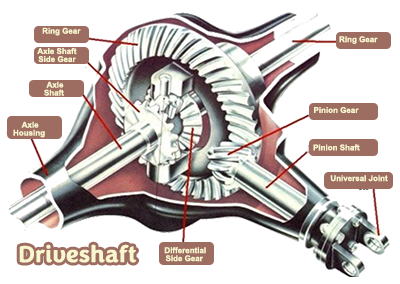

The drive shaft confidently transfers the engine torque from the gearbox or differential to the wheels. It compensates for all variations in angle or length resulting from manoeuvring and deflection for perfect synchronisation between joints.

The drive shaft confidently transfers the engine torque from the gearbox or differential to the wheels. It compensates for all variations in angle or length resulting from manoeuvring and deflection for perfect synchronisation between joints.  Front wheel drive cars have drive shafts that confidently consist of an outboard fixed joint, an inboard constant velocity joint, and a connecting shaft. The anti-lock system ring and torsion damper are essential elements included in the product.

Front wheel drive cars have drive shafts that confidently consist of an outboard fixed joint, an inboard constant velocity joint, and a connecting shaft. The anti-lock system ring and torsion damper are essential elements included in the product.

The design of the outboard fixed ball joint, also known as the constant velocity joint, has a rich history dating back to the pre-war era.

The driveshaft is recognised as being among the most crucial components, responsible for transmitting rotational power from the engine to the rear differential. Essentially a rotating tube that connects these two components the driveshaft ( or propshaft as it is sometimes known) enables the transfer of torque to the wheels. The mechanism responsible for transmitting power from the front to the back of the device is what enables it to spin. The gearbox transfers torque to the differential, which in turn transmits the torque to the wheels, enabling the vehicle to move.

![]()

![]() Check the driveline, universal joints and the driveshaft for any signs of leaks. If you notice a leak, have it repaired as soon as possible to prevent further damage to the system.

Check the driveline, universal joints and the driveshaft for any signs of leaks. If you notice a leak, have it repaired as soon as possible to prevent further damage to the system.

![]()

If you notice any vibrations or wobbling coming from the driveshaft, it could be a sign of a problem.

If you notice any vibrations or wobbling coming from the driveshaft, it could be a sign of a problem.

Some of the most common causes of driveshaft vibration are either slip splines or U-joints beginning to show signs of wear and tear, other components that have gradually moved out of balance. Misaligned angles are another common cause as well as yokes that have gradually been driven out of phase thus approaching too close to the critical speed range.

No matter the symptom, vibrations and shuddering are an almost certain indication that the driveshaft is in the verge of failure. If and when the bushings or U-joint wear out excessive driveshaft vibration will be clearly felt. This can be caused by a damaged or worn universal joint, or an out-of-balance driveshaft.

![]() Any unusual noises coming from the driveshaft, such as clicking or clunking sounds in most cases indicate a problem with the universal joints or other components and should be addressed as soon as possible.

Any unusual noises coming from the driveshaft, such as clicking or clunking sounds in most cases indicate a problem with the universal joints or other components and should be addressed as soon as possible.

![]() The universal joints are what allow the driveshaft to flex and move as the suspension and wheels of the vehicle move up and down. The first stage is to lift the vehicle and allow it to rest securely on the jack stands.

The universal joints are what allow the driveshaft to flex and move as the suspension and wheels of the vehicle move up and down. The first stage is to lift the vehicle and allow it to rest securely on the jack stands.

The grease fitting point is positioned to the middle of the U-Joint. Begin filling the grease into the filling home with a grease gun and the appropriate size grease gun coupler. Continue filling the grease until clean grease emerges from the filing place.

The grease fitting point is positioned to the middle of the U-Joint. Begin filling the grease into the filling home with a grease gun and the appropriate size grease gun coupler. Continue filling the grease until clean grease emerges from the filing place.

For U-Joints, a certified moly grease should only be used, These joints need to be lubricated to keep them functioning smoothly. Check the manual of your car to find out how often they should be lubricated and use the recommended grease.

![]()

Make sure that the driveshaft is properly aligned and that the angle is within the manufacturer's specifications.

Make sure that the driveshaft is properly aligned and that the angle is within the manufacturer's specifications.

To align a driveshaft a spirit level protractor should be placed about midway between the transmission and the differential on the driveshaft. Read and record the protractor scale angle and note whether the driveshaft points up or down at the front.

An improperly aligned driveshaft can cause vibration and wear on the universal joints.

![]() If rust is present, have it removed and treated to prevent further corrosion. Rust can cause damage to the driveshaft over time.

If rust is present, have it removed and treated to prevent further corrosion. Rust can cause damage to the driveshaft over time.

It's important to keep in mind that classic cars may have different driveshaft system than the modern cars, it's always better to consult the manual of the particular model being maintained.

Regular maintenance and inspection can help extend the life of your classic car's driveshaft and minimise costly repairs in the future.